Description

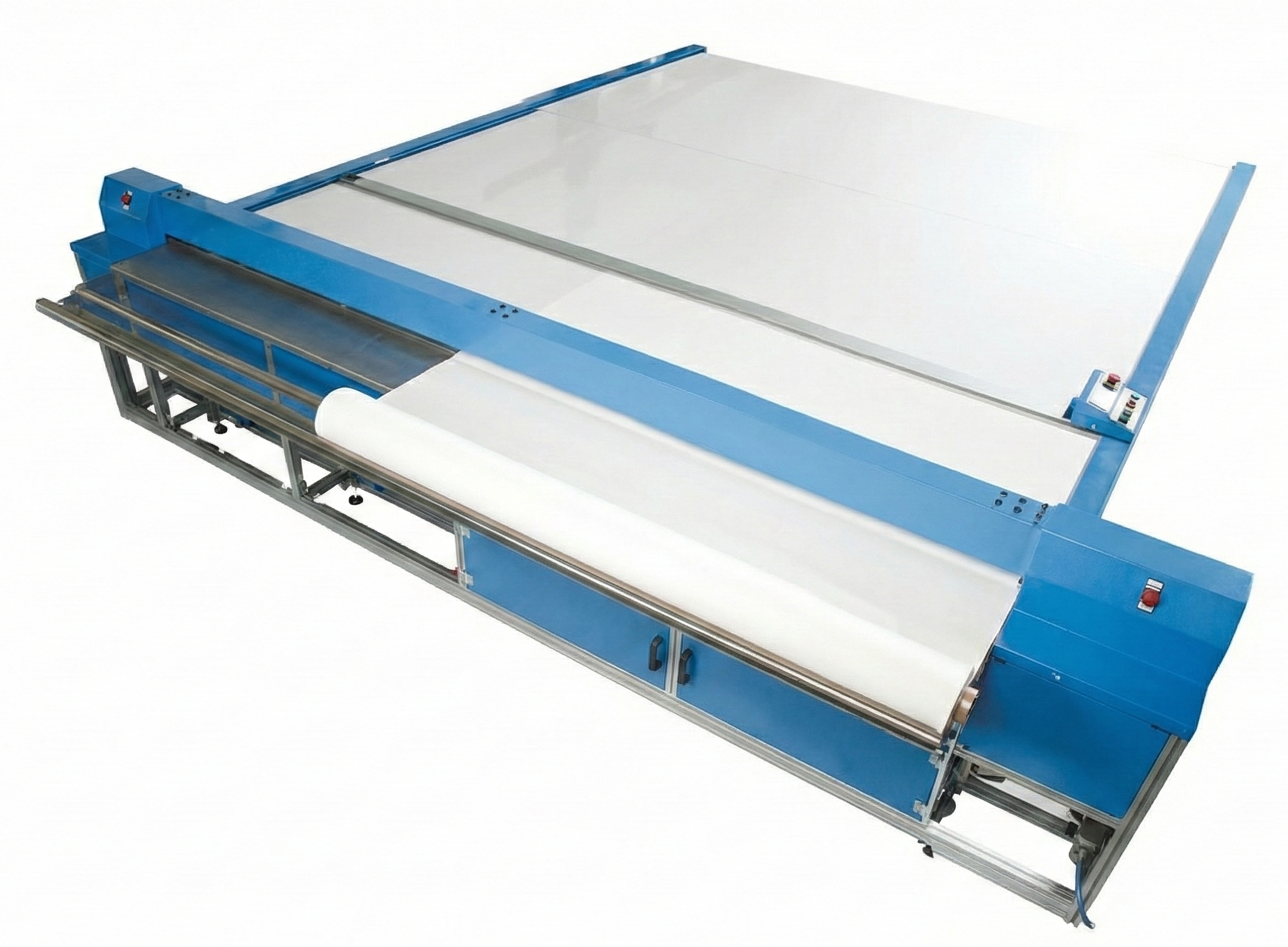

BMO SRC-SLM: An Efficient & Cost-Optimized Vertical Blind Cutting Solution

In vertical blind production, maximum speed is not always the top priority. Many manufacturers seek a balance between productivity, stability, and investment budget. The BMO SRC-SLM is the answer to that need - a dedicated vertical blind cutting machine featuring a multi-blade cutting system, simple operation, and cost efficiency.

1. Reasonable Investment Cost – Maximum Cutting Efficiency

Designed with a “cost-effective” philosophy, the SRC-SLM eliminates overly complex features and focuses on its core function: delivering clean, stable blind cutting.

The machine uses a razor blade cutting system. The advantages of this type of blade are extremely sharp, thin, and clean cutting lines, making it ideal for commonly used vertical blind fabrics. Moreover, replacement blades are inexpensive and widely available, significantly reducing monthly operating costs (consumables) for workshops.

2. Dual Tension Control (Mechanical & Electronic)

Although positioned as an economical model, the SRC-SLM does not compromise on critical fabric quality features. The machine is equipped with a combined electronic and mechanical tension control system.

This system operates synchronously on both the unwinding and rewinding shafts, ensuring that finished blind rolls are neat, flat, and free from fabric misalignment.

3. Smart Cantilever Design & Quick Locking System

To support fast and efficient operator handling, BMO equips the SRC-SLM with highly practical mechanical designs:

Cantilever-type shafts: Two air-expanding rewinding shafts are cantilever-designed, allowing operators to easily install and remove finished blind rolls with minimal effort.

Quick locking system: Installed on both the unwinding and rewinding shafts. With a single lever action, the air shaft can be locked or released, minimizing roll changeover time.

4. Simple & Flexible Operation

The machine’s control system is simplified for maximum ease of use. Operators can easily adjust the cutting speed to suit their skill level or the type of fabric being processed.

The machine offers high customization flexibility with an available cutting width ranging from 2,000 mm to 2,600 mm (or other sizes upon customer's request). The minimum cutting width is 30 mm, meeting the requirements of most vertical blind fabric specifications.

Conclusion

The BMO SRC-SLM is a “reliable and durable” choice for vertical blind manufacturers. With low initial investment, inexpensive blade costs, and essential productivity features such as cantilever shafts and tension control, this machine delivers the fastest return on investment within BMO’s automatic blind cutting machine lineup.

Contact us today to receive a detailed quotation for BMO specialized blind cutting machines.