Description

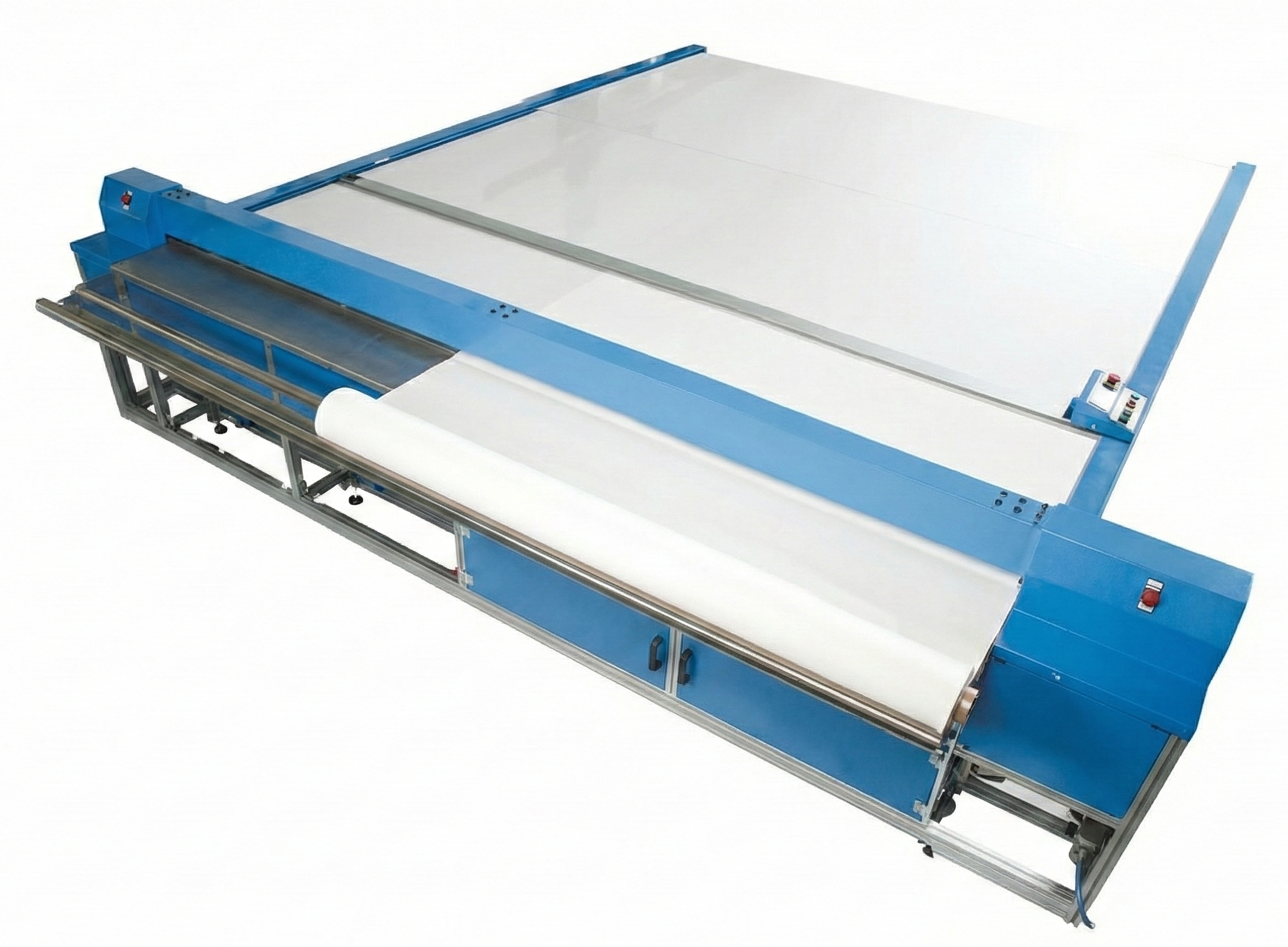

BMO SCM-AS: Versatile Industrial Fabric Hot Cutting System & Digital Operation Management

In the field of industrial textile processing, the BMO SCM-AS is positioned as a specialized vertical blind fabric cutting machine featuring a multi–hot knife system, with a strong focus on high flexibility and production process management. The equipment combines advanced hot cutting technology with a digital control system, enabling precise processing of a wide range of materials from thin fabrics and elastic materials to heavy-duty, high-load belts.

1. Process Optimization with Digital Memory

The key distinction of the SCM-AS lies in its ability to digitize operating procedures. The machine is equipped with an intelligent data storage system that can memorize the technical parameters of up to 30 frequently used product codes.

This feature helps manufacturers standardize production processes, shorten machine setup time when switching between different orders, and minimize errors caused by manual data input.

2. Capability to Handle Diverse and Complex Materials

The BMO SCM-AS is designed to meet stringent material requirements in industrial environments:

Thick and load-bearing materials: Through hot knife heating time control, the machine can cut and seal the edges of thick materials or heavy-duty industrial belts while maintaining clean, sharp cuts without fraying.

Highly elastic materials: The run-mode setup function allows the machine to cut flexible fabrics or rubber-fiber–blended textiles. This mechanism controls material deformation, ensuring accurate finished dimensions after cutting.

3. Enhanced Accuracy with Optional Encoder

To meet strict quality standards, the SCM-AS offers the option to integrate an encoder. This external device monitors and feeds back cutting length in real time, providing higher accuracy compared to traditional mechanical measuring methods.

4. Safe and Stable Operation

The system is designed with integrated standard safety features:

Material sensor: Automatically detects and stops operation when the input fabric runs out, protecting the cutting knife and the machine system.

Flexible control: Supports both automatic operation and manual control modes, facilitating inspection, maintenance, or initial material alignment.

Integrated design: The machine is supplied with a standard fabric roll stand, ensuring stable and consistent material feeding.

Conclusion

The BMO SCM-AS is a comprehensive industrial hot cutting solution that combines powerful material handling capabilities with intelligent production management. It is the ideal choice for modern production lines that demand high flexibility and strict control over output quality.

Contact us today to receive a detailed quotation for BMO specialized blind cutting machines.