Description

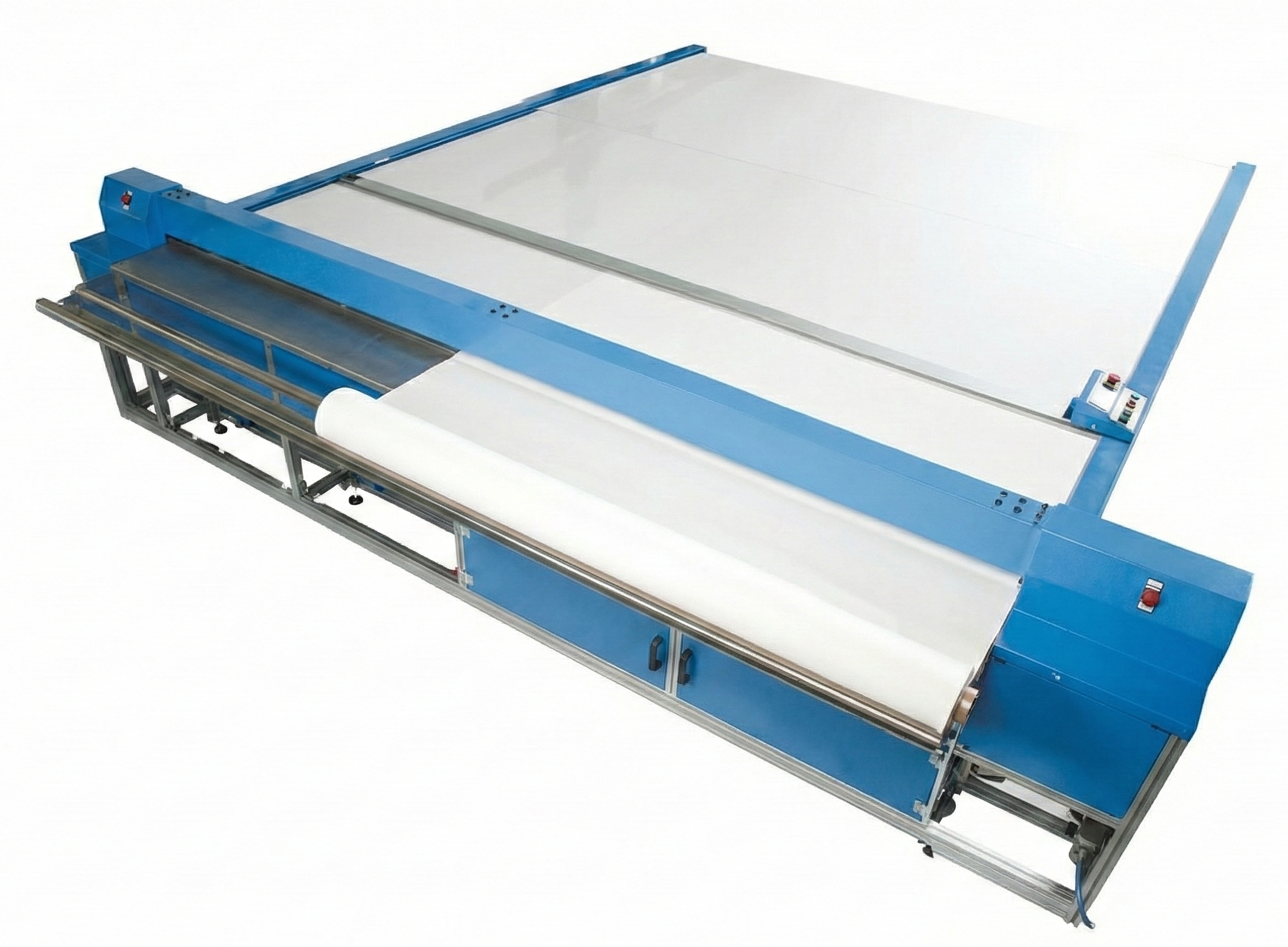

BMO SCM-130CS: A Versatile “2-in-1” Vertical Blind Fabric Cutting Solution – Flexible Switching Between Hot & Cold Cutting Blades

In today’s modern manufacturing environment, the need to process a wide variety of materials on a single production line is a common challenge. The BMO SCM-130CS is the answer to this demand for versatility. It is one of the most flexible cutting machines available, allowing businesses to easily switch between hot cutting and cold cutting modes on the same device, meeting even the most stringent requirements from thick webbing and elastic bands to blind fabrics.

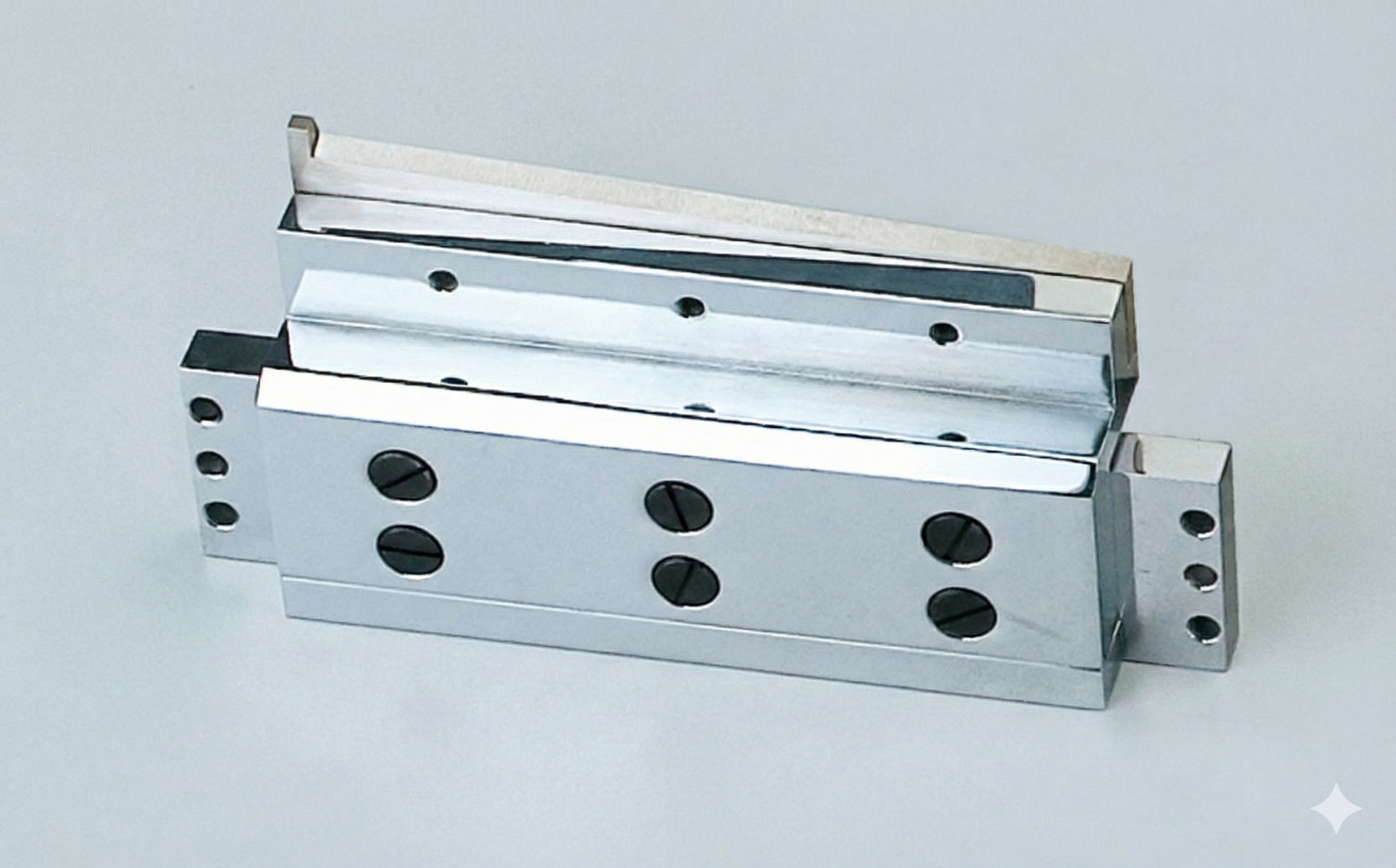

1. Flexible Dual-Blade Technology: Optimized for Every Material

The core strength of the SCM-130CS lies in its versatility, enabled by its ability to interchange between two cutting systems:

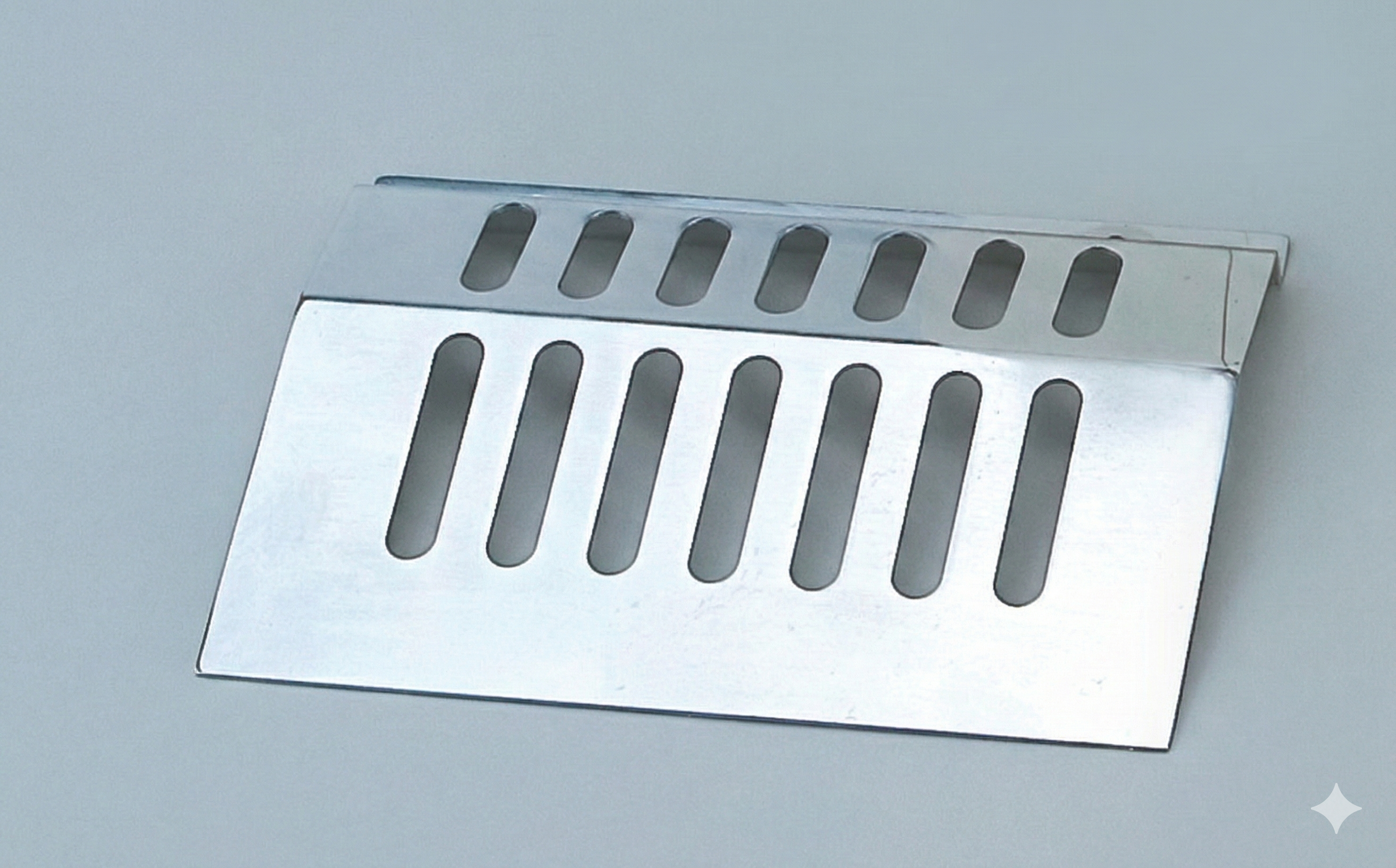

Cold Cut Mode: Using a sharp blade to quickly and cleanly cut materials such as Velcro straps (hook-and-loop), webbing and labels, with a speed of up to 34–35 cuts per minute.

Hot Cut Mode: Using heat to cut and seal the edges of synthetic fabrics, nylon cords, vertical blind slats, and curtain strings, ensuring clean edges without fraying.

With just a simple mode setting, the machine automatically optimizes its operating process according to the blade type in use, turning it into a multifunctional tool for any processing factory.

2. Powerful Handling of Thick & Elastic Materials

Beyond standard fabric cutting, the versatility of the SCM-130CS is further demonstrated by its ability to handle challenging materials:

Cutting heavy materials: Thanks to precise control of the hot blade heating time, the machine can cleanly cut thick webbing, high-load straps, or heavy fabrics while maintaining smooth, high-quality edges.

Cutting elastic materials: The machine is equipped with a dedicated setting for soft, highly elastic materials such as woven elastic tapes (with rubber fibers) and drawstrings, ensuring high cutting length accuracy even when the material stretches during feeding.

3. Intelligent & Precise Operation

To fully support diverse production requirements, the machine integrates advanced assistance technologies:

High accuracy: A calibration function ensures greater precision in cutting length.

Efficient management: The machine’s memory can store parameters for up to 30 different jobs. You can pre-save cutting specifications for webbing, elastic bands, blinds, and more, and switch between them instantly without time-consuming reconfiguration.

Conclusion

The BMO SCM-130CS is the ideal choice for businesses that prioritize flexibility. Instead of investing in multiple machines for different processes, the SCM-130CS delivers a true “all-in-one” solution, ready to handle any cutting order, regardless of material type.

Contact us today to receive a detailed quotation for BMO specialized blind cutting machines.