Description

BMO SRC-TUC-A2: Table-Type Blind Cutting Solution with Intelligent Dual Cutting Technology

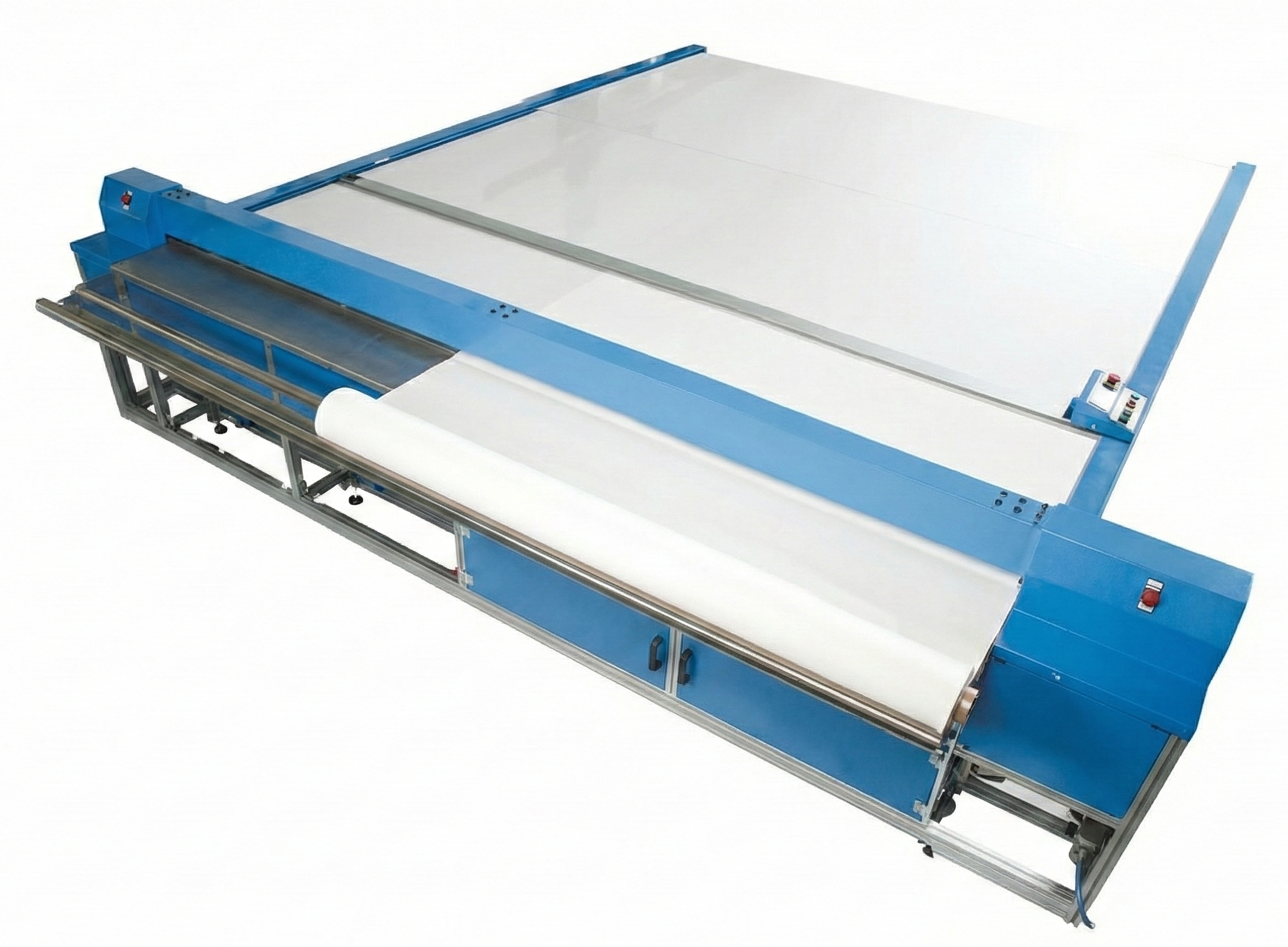

For large-width roller blinds or technical fabrics that require absolute flatness during processing, table-type cutting machines are always the preferred choice. The BMO SRC-TUC-A2 not only meets the need for a spacious and stable cutting table, but also represents a breakthrough by integrating two cutting technologies in parallel: Ultrasonic cutting and Crush blade cutting with fully automatic switching capability.

1. Dedicated Table-Type Design

Completely different from vertical-frame cutting machines, the SRC-TUC-A2 is specifically designed with a flat table structure. This design offers a major advantage when handling slippery or oversized materials, allowing operators to easily observe, align, and control the fabric surface before executing the cutting command.

The machine provides an extremely large effective cutting width, with a standard size starting from 3,600 mm and expandable up to 5,000 mm (customized according to customer requirements). This makes it an ideal solution for producing large-format office curtains such as tarpaulins, projection screens, and oversized roller blinds.

2. Dual-Blade Technology & Automatic Switching

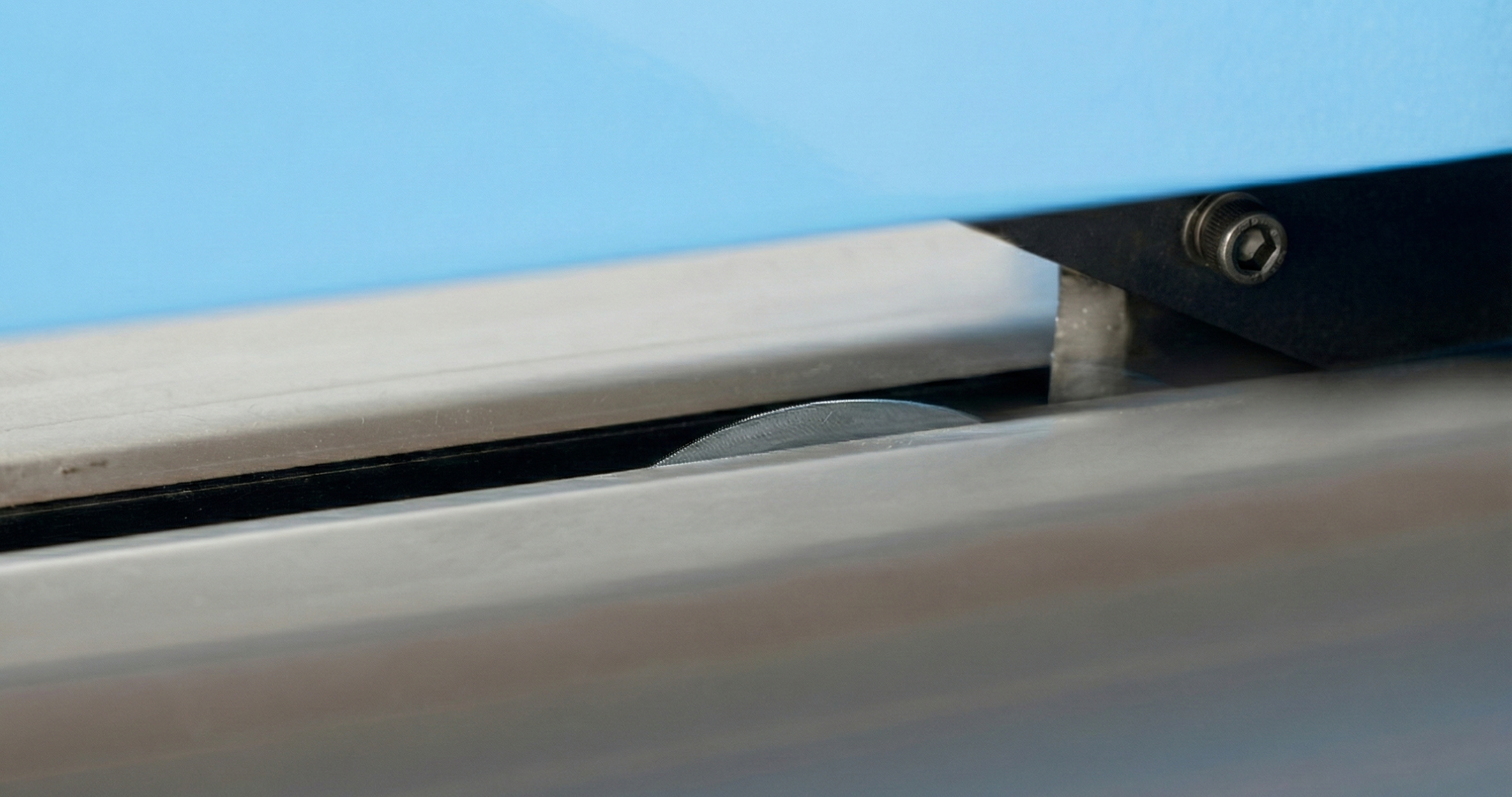

Flexibility is the SRC-TUC-A2’s strongest advantage. The machine is equipped with two of the most advanced cutting blades available today:

Ultrasonic blade: Used to cut and simultaneously seal fabric edges, preventing fraying on blind fabrics and industrial textiles.

Crush blade: Uses compression force to cut through thick fabrics, canvas, or tough materials.

What truly sets this machine apart is its automatically changeable blade feature. Instead of time-consuming manual blade replacement, operators simply select the desired mode on the touchscreen, and the machine automatically switches to the appropriate blade for the fabric type, significantly optimizing production time.

3. Safe Operation & Process Optimization

To ensure high precision over long cutting paths, the SRC-TUC-A2 is integrated with intelligent support features:

Automatic stopper: A critical safety feature that immediately stops the cutting head at the end of the cutting cycle or when an abnormal condition is detected. This helps prevent operational accidents, protects operators, and avoids blade damage due to collisions.

Automatic fabric unwinding & rewinding system: Makes it easier to spread heavy fabric rolls onto the cutting table and neatly collect the material after cutting.

4. Simple & Efficient Operation

All machine functions are controlled via a touchscreen interface combined with a PLC controller. The intuitive interface allows users to easily set cutting lengths, select blade types, and monitor operating speed.

The machine operates on single-phase power (110V–240V) and standard compressed air at 6 kg/cm², making it easy to install in most factories.

Conclusion

The BMO SRC-TUC-A2 is a perfect combination of the stability of a table-type cutting machine and the refinement of ultrasonic cutting technology. If your factory specializes in large-width roller blind orders and requires a versatile machine capable of both ultrasonic cutting and crush cutting, this is the most accurate investment you can make.

Contact us today to receive a detailed quotation for BMO specialized blind cutting machines.