Description

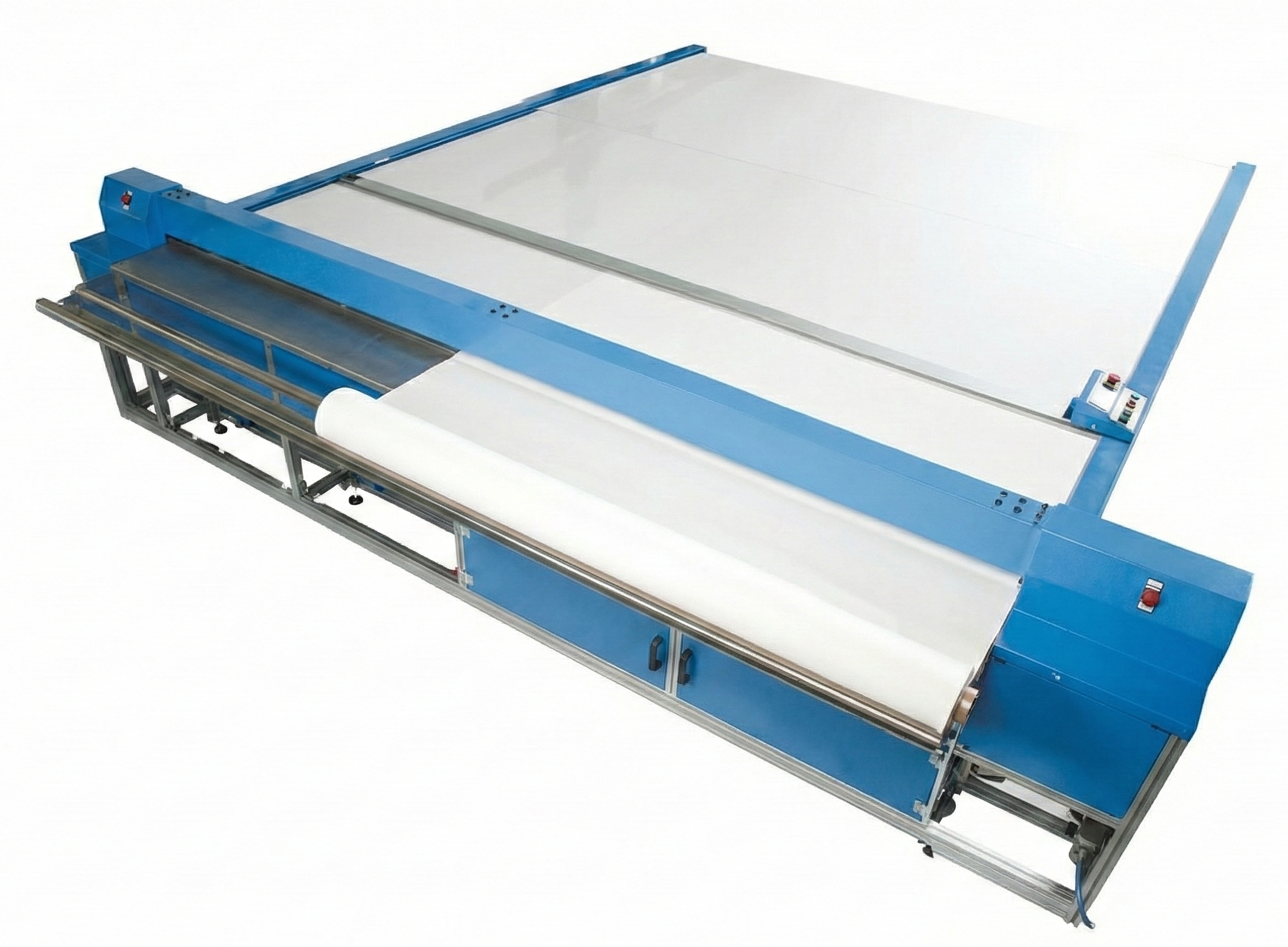

BMO SVC-130: Automatic Cutting – Punching – Creasing Machine for Vertical Blind Fabric

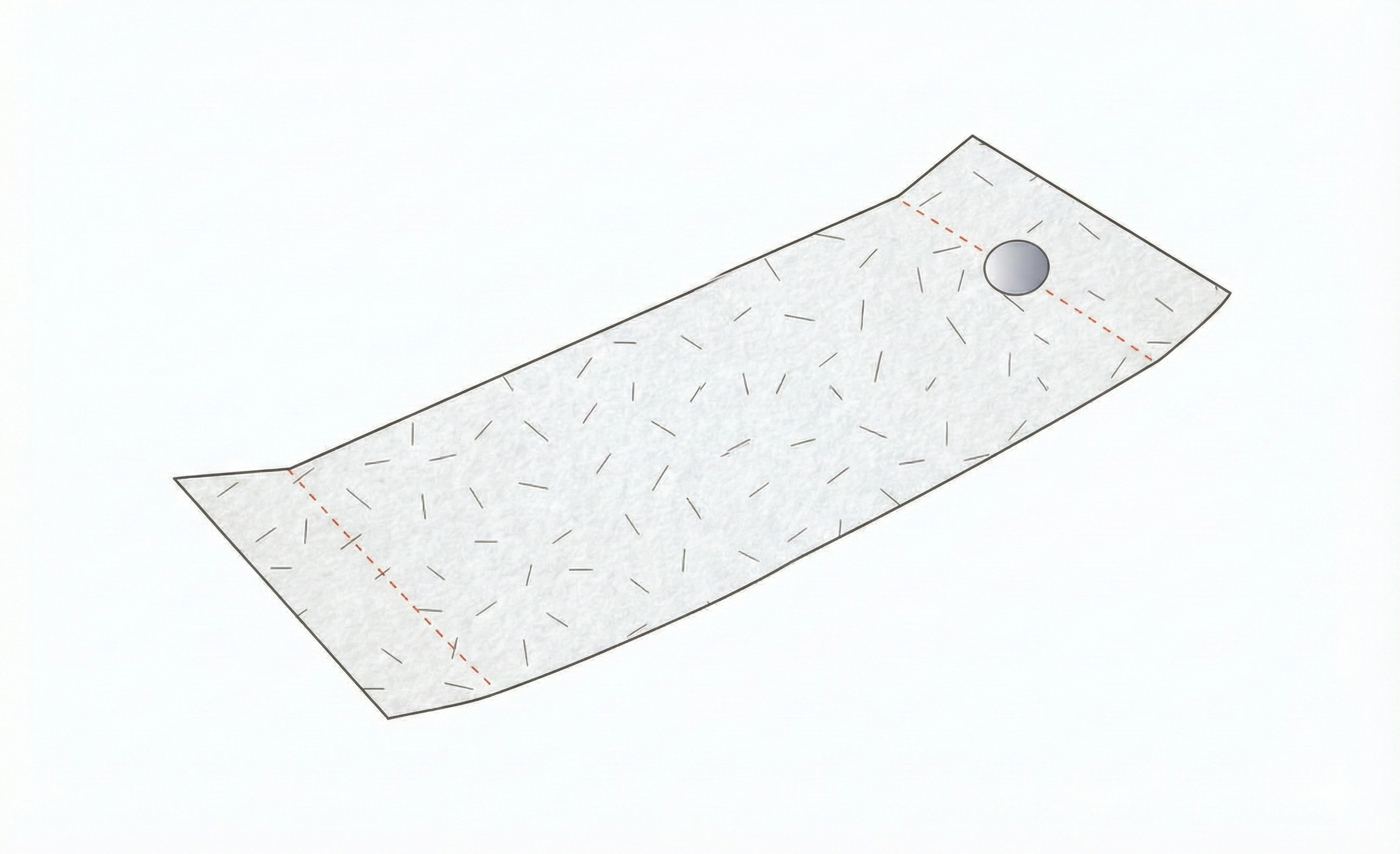

In the vertical blind production process, cutting individual slats, then manually punching hanging holes and folding hems is the most time- and labor-intensive stage. The BMO SVC-130 was developed to fully automate this process. With just one setup operation, the machine produces finished blind slats that are ready for assembly, helping businesses maximize labor cost savings.

1. Breakthrough “3-in-1” Technology

The greatest advantage of the SVC-130 is its ability to perform three operations simultaneously in a single run:

Cut: Cuts the blind slat to the preset length

Crease: Forms precise crease lines for accurate hemming

Punch: Punches holes for cords or hanging hooks directly on the slat

Instead of using three separate machines or performing each step manually, the SVC-130 integrates everything into one closed-loop process, ensuring 100% consistency.

2. High Precision Through Intelligent Feeding

To guarantee accurate cutting length, the machine is equipped with a tension-eliminating feeding system. This system feeds the fabric into the cutting chamber in a completely relaxed, natural state without stretching. Combined with an encoder and calibration function, the machine ensures consistently accurate finished lengths, eliminating errors caused by fabric elasticity.

3. Digital Operation & Smart Memory System

The BMO SVC-130 is designed to maximize user convenience:

Operation history: The machine can store up to 30 frequently used cutting programs. Common blind sizes only need to be set once and can be reapplied anytime without re-entering data.

Easy control: A fully digital control system makes operation simple and intuitive.

Smart sensors: Automatic fabric-end detection stops the machine immediately to protect the equipment and prevent cutting errors.

4. Flexible & Versatile Performance

Although specifically designed for vertical blind fabrics with an available cutting width of 130 mm, the machine offers impressive flexibility. Thanks to special operating mode settings, it can also handle soft and highly elastic fabrics, such as woven fabrics containing rubber fibers. The machine uses a cold knife, making it suitable for most common vertical blind materials on the market.

Conclusion

The BMO SVC-130 is a compact automation solution that delivers outstanding efficiency. It completely eliminates manual labor in vertical blind slat processing, enabling your workshop to operate more professionally, faster, and with greater precision.

Contact us today to receive a detailed quotation for BMO specialized blind cutting machines.