Description

BMO SRC-M3: Ultrasonic Cutting Technology – New Standard - New Technology

In modern curtain manufacturing, especially when working with synthetic or coated fabrics, ensuring fray-free cut edges is a decisive factor in product aesthetics. The BMO SRC-M3 automatic blind cutting machine was developed to completely solve this challenge. Building on the efficient multi-blade cutting capability of its predecessor, the SRC-M3 is significantly upgraded with an ultrasonic cutting system, delivering the most refined and flawless cutting results.

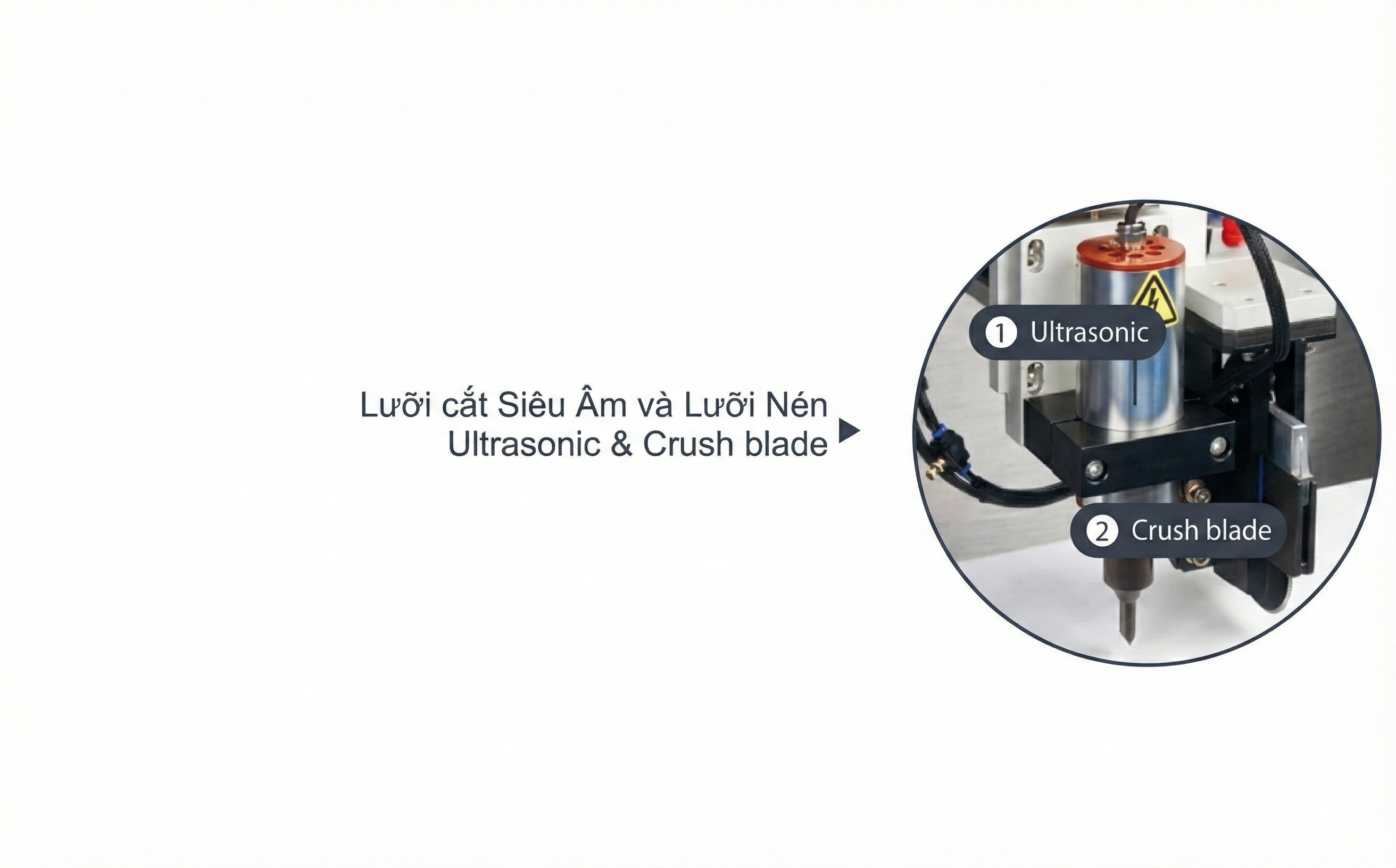

1. Breakthrough Ultrasonic Cutting Technology

The most distinctive feature of the SRC-M3 lies in its cutting system. Instead of relying solely on conventional mechanical blades, the machine is equipped with ultrasonic cutting blades combined with crush blades.

Ultrasonic technology operates on the principle of high-frequency vibration, generating just enough heat to cut through the fabric while simultaneously sealing the cut edge. This completely eliminates fraying and fiber shedding at the edges—a common issue when cutting roller blinds, combi blinds, and other high-tech curtain fabrics. As a result, curtain panels achieve perfectly finished edges without the need for additional overlocking or heat-sealing processes.

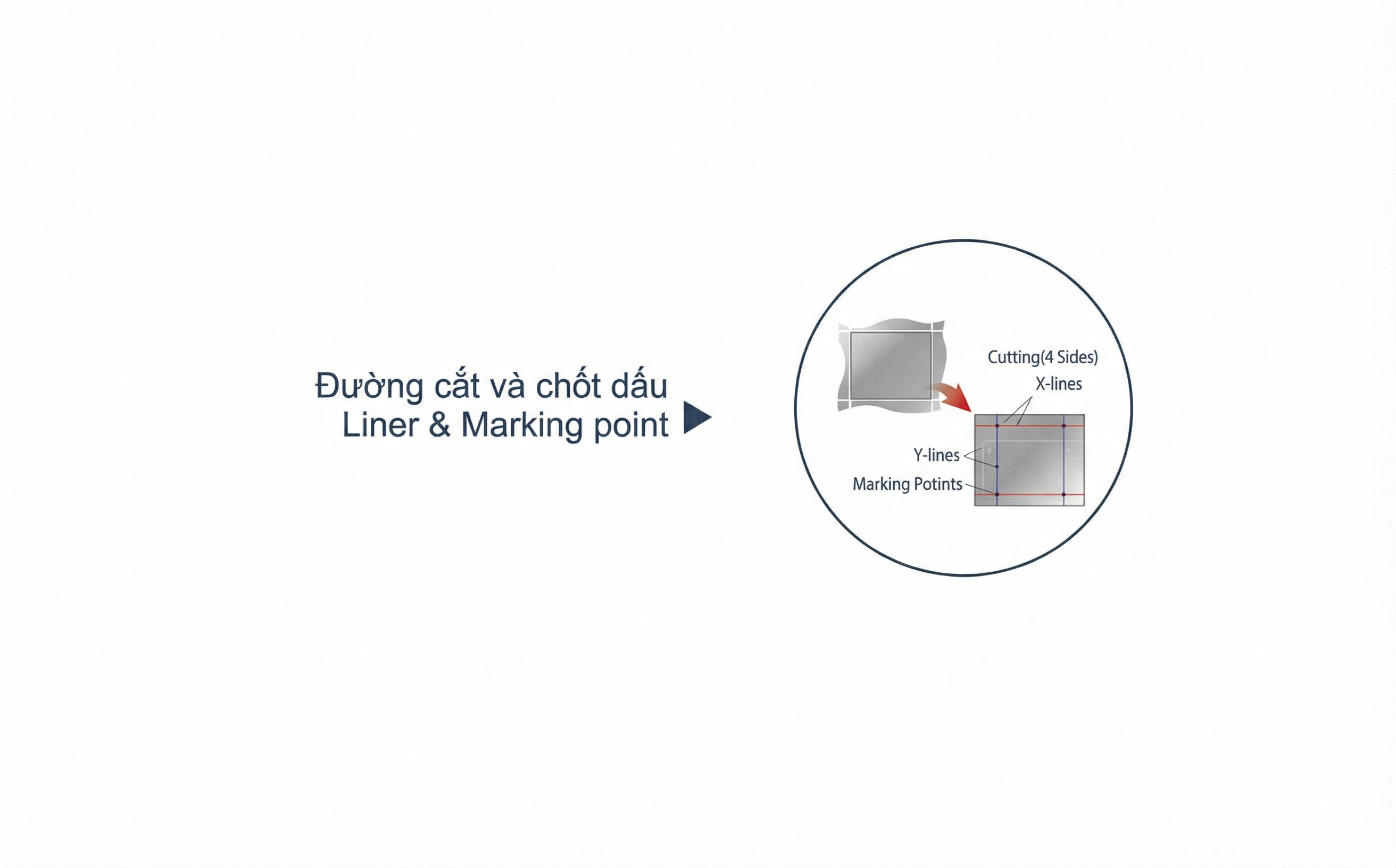

2. Dual Efficiency: Simultaneous X–Y Axis Cutting

To maximize factory productivity, the SRC-M3 retains the ability to perform longitudinal cutting (Y-axis) and cross cutting (X-axis) simultaneously.

The system is powerfully configured with three blade sets on the Y-axis and one blade set on the X-axis. This dual-axis cutting operation reduces processing time by up to 50% compared to single-axis cutting machines, transforming raw fabric rolls into finished curtain panels in a matter of moments.

3. Intelligent & High-Precision Control

The SRC-M3 not only delivers beautiful cuts but also ensures exceptional accuracy through advanced operational technologies:

Electronic tension control: Automatically adjusts fabric tension to suit different materials and working conditions, ensuring the fabric remains flat and free from distortion during cutting.

User-friendly interface: All operations are controlled via a touchscreen combined with a PLC system, making parameter setup quick and intuitive.

Data management: The machine supports cutting data transfer and storage via USB, simplifying the management of repeat curtain patterns.

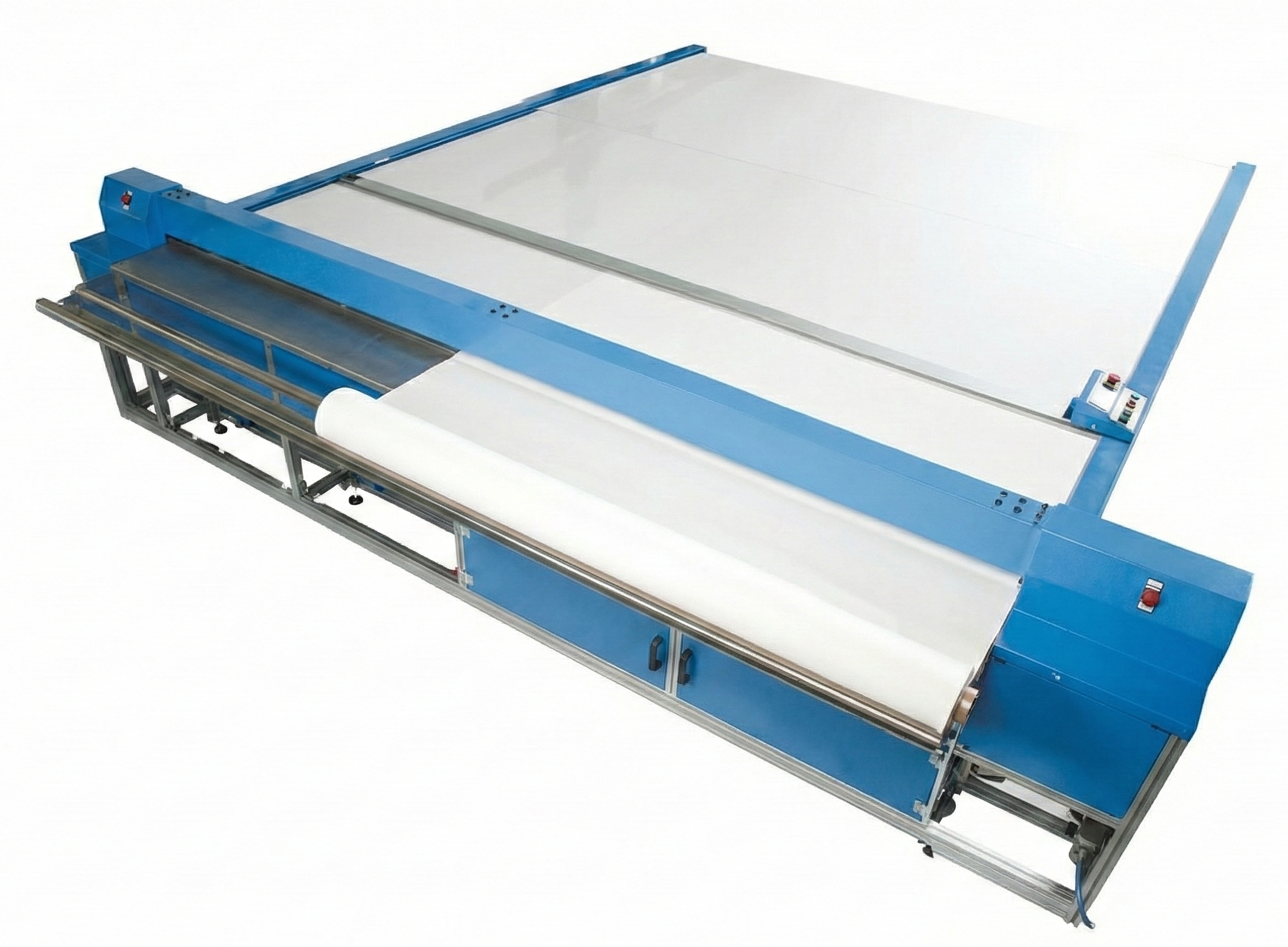

4. Industrial Design & High Customization

The SRC-M3 offers outstanding stability and robustness even at high operating speeds. It provides a flexible effective cutting width ranging from 2,700 mm to 3,200 mm, larger sizes can be produced to meet specific customer needs.

In addition, manufacturers can integrate optional upgrades such as marking and lining devices to support sewing and assembly processes after cutting.

Conclusion

If you are producing high-end curtain products that demand impeccable edge finishing, the BMO SRC-M3 with ultrasonic cutting technology is the most “value-for-money” investment you can make. Beyond boosting productivity, the SRC-M3 elevates your product quality to a new level with sharp, flawless, and defect-free cuts.

Contact us today to receive a detailed quotation for BMO specialized blind cutting machines.