Description

BMO-SE35: The Standard Rolled Fabric Spreading Machine for Garment Production Lines

In today’s industrial garment factories, rolled fabric remains the most common form of fabric material. Having a specialized spreading machine that operates stably with a reasonable investment cost is therefore a top priority. The BMO-SE35 is the perfect answer to this need, smoothly handling a wide variety of rolled fabrics with flexibility and long-term durability.

1. A Specialized Solution for Rolled Fabrics

The BMO-SE35 is positioned as a specialized machine for rolled fabrics. It is optimally designed to flexibly process fabric rolls with a maximum roll diameter of up to 400 mm.

This flexibility in load capacity and size allows the machine to serve a wide range of orders, from woven fabrics and knitted fabrics to elastic materials such as Spandex.

2. Next-Generation Tension Control Technology

The BMO-SE35 is equipped with a new-generation digital tension control system using Servo motors to precisely manage pulling force and automatically adjust torque to suit each fabric type.

Whether handling Spandex or rigid woven fabrics, the SE35 ensures that fabric layers are spread flat and free from dimensional deformation. This eliminates errors at the spreading stage, ensuring the quality of semi-finished products after cutting.

3. Full Touchscreen Interface & Smart Production Management

The BMO-SE35 eliminates complex mechanical buttons and replaces them with a fully touchscreen control system. Its intuitive interface allows operators to easily input dimensions and monitor parameters with just a few touches.

Notably, the machine is ready for the smart factory 4.0 trend thanks to its support for MES (Manufacturing Execution System) integration. This feature enables direct data connection with the central management system, allowing business owners to transparently monitor operating performance and order progress in real time.

4. Multiple Spreading Modes & Optimized Automation

To meet complex cutting marker requirements, the BMO-SE35 flexibly supports multiple fabric spreading modes, including one-way spreading and zigzag spreading. This versatility helps manufacturers optimize processes for each specific style or order.

In addition, the machine integrates a range of automated features to reduce operator workload:

Precision alignment: Automatic fabric edge alignment and automatic cutter lifting based on the actual thickness of the fabric layers.

Convenient operation: Functions such as automatic detection of spreading distance, automatic rewinding, and "home position" ensure smooth and efficient operation.

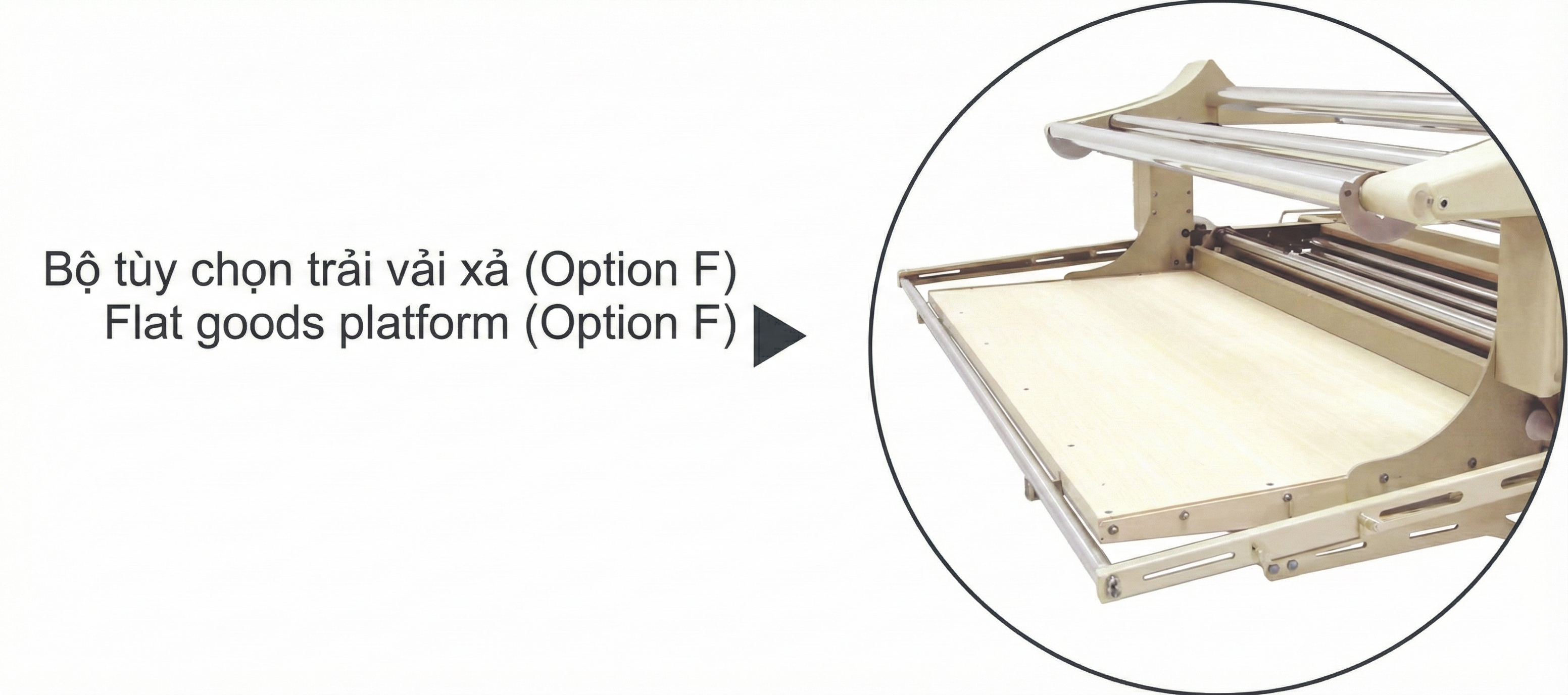

BMO-SE35_F Version: This version is additionally equipped with an optional folded fabric spreading mode, allowing flexible handling of both rolled fabric and folded fabric on the same machine.

5. Conclusion

With its flexible rolled fabric handling capability and versatile zigzag spreading mode, the BMO-SE35 is a “right and sufficient” investment for most garment factories today. The perfect synergy between Servo technology and intelligent processing has firmly established the SE35 as a standout choice for all rolled fabric handling processes.

Contact us today for in-depth consultation and firsthand experience of the performance of BMO fabric spreading machines.