Description

BMO MFS-ST200: A Heavy Fabric Spreading “Warrior”

Handling heavy fabric rolls such as denim, felt, or other heavyweight materials is always a challenge for conventional fabric spreading machines. The BMO MFS-ST200 was created to conquer this challenge. It is a specialized machine designed with a robust mechanical structure, optimized specifically for woven fabrics, nonwoven materials and heavy fabric rolls.

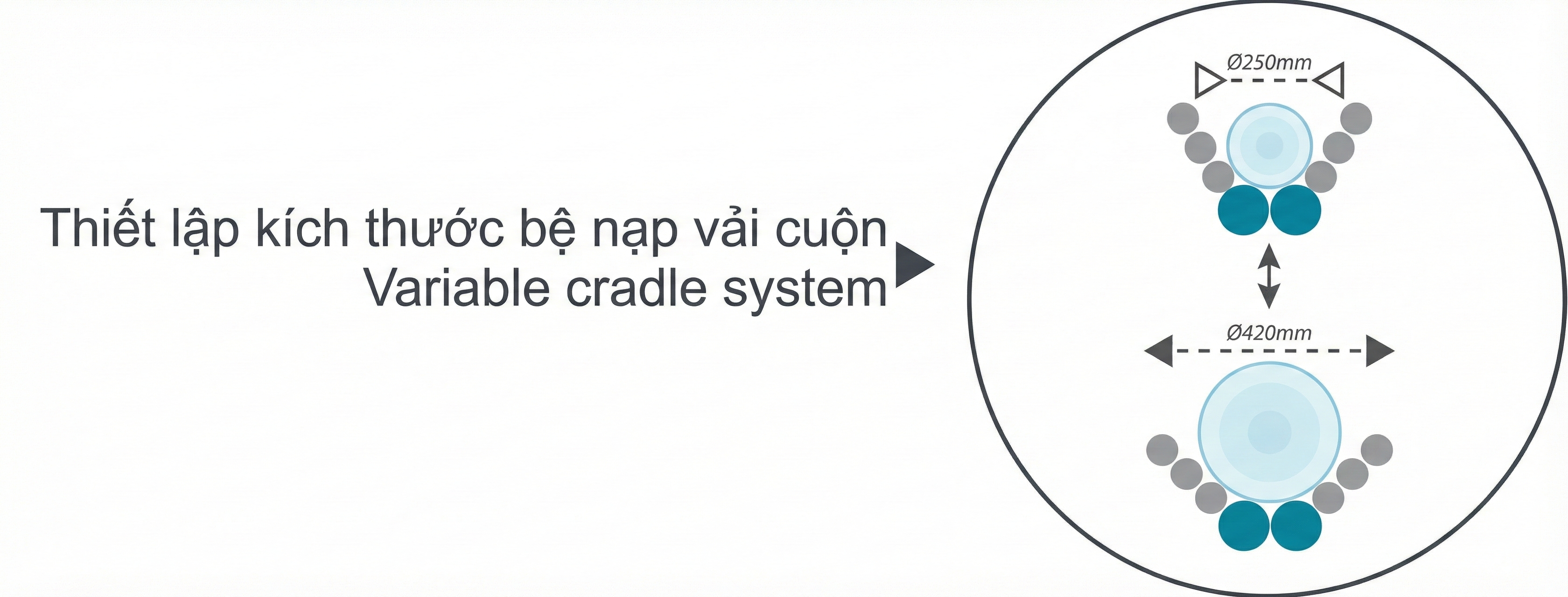

1. Variable Cradle System

The biggest difference between the MFS-ST200 and standard models is its Variable Cradle System. Instead of using a fixed-size holder, the machine’s cradle can flexibly expand to securely support fabric rolls with large diameters ranging from 250 mm to 420 mm.

This design allows stable operation without vibration, even when handling extremely heavy denim or felt rolls, ensuring smooth and consistent fabric unwinding.

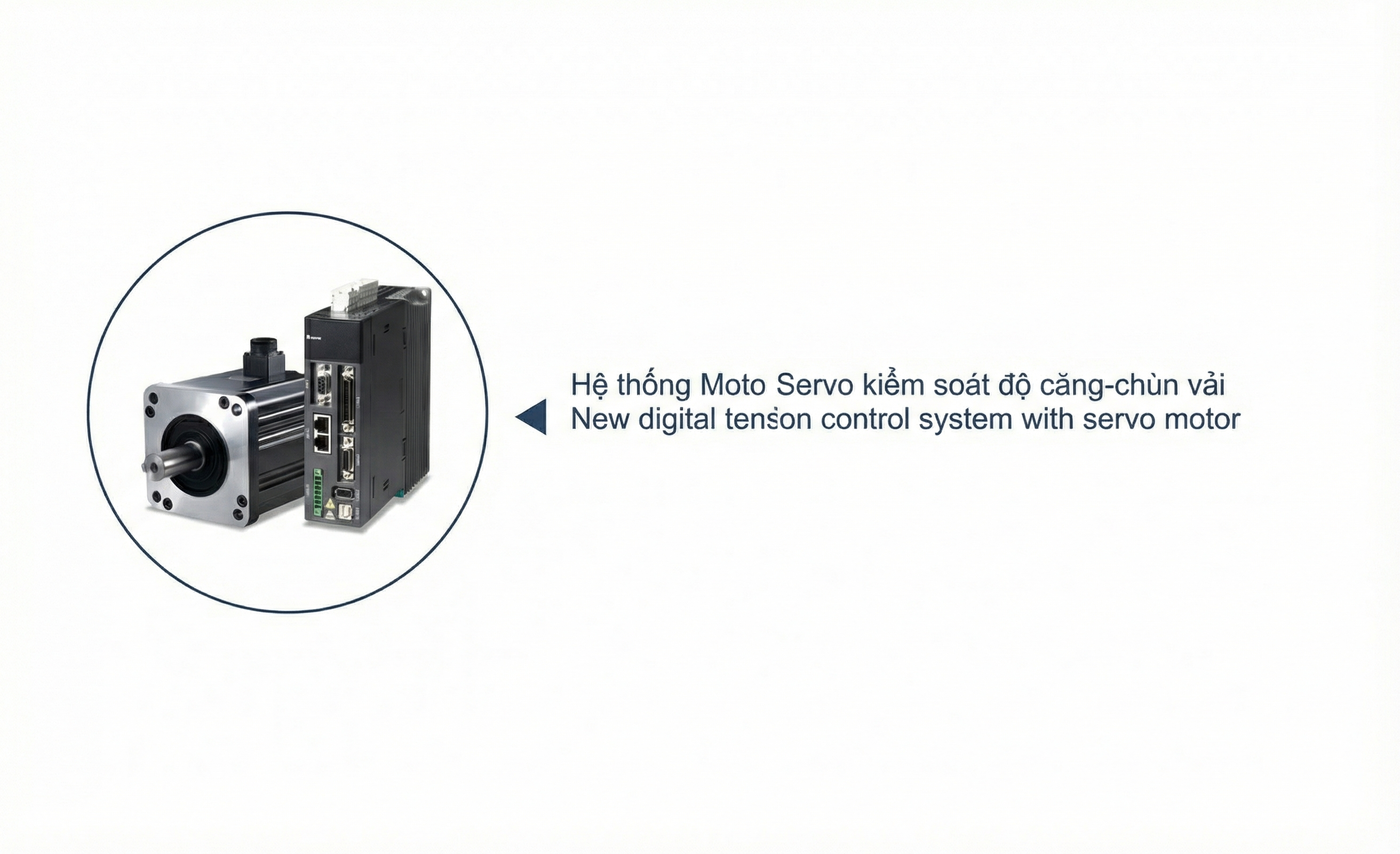

2. Digital Tension Control (Servo Control)

Although built for heavy fabrics, the MFS-ST200 is remarkably “delicate” when processing elastic fabrics such as spandex. The machine is equipped with a digital tension control system powered by a servo motor.

This system continuously monitors and adjusts pulling force in real time, ensuring tension-free fabric spreading. As a result, whether working with elastic knits or thick, rigid fabrics, all fabric layers remain flat and free from deformation.

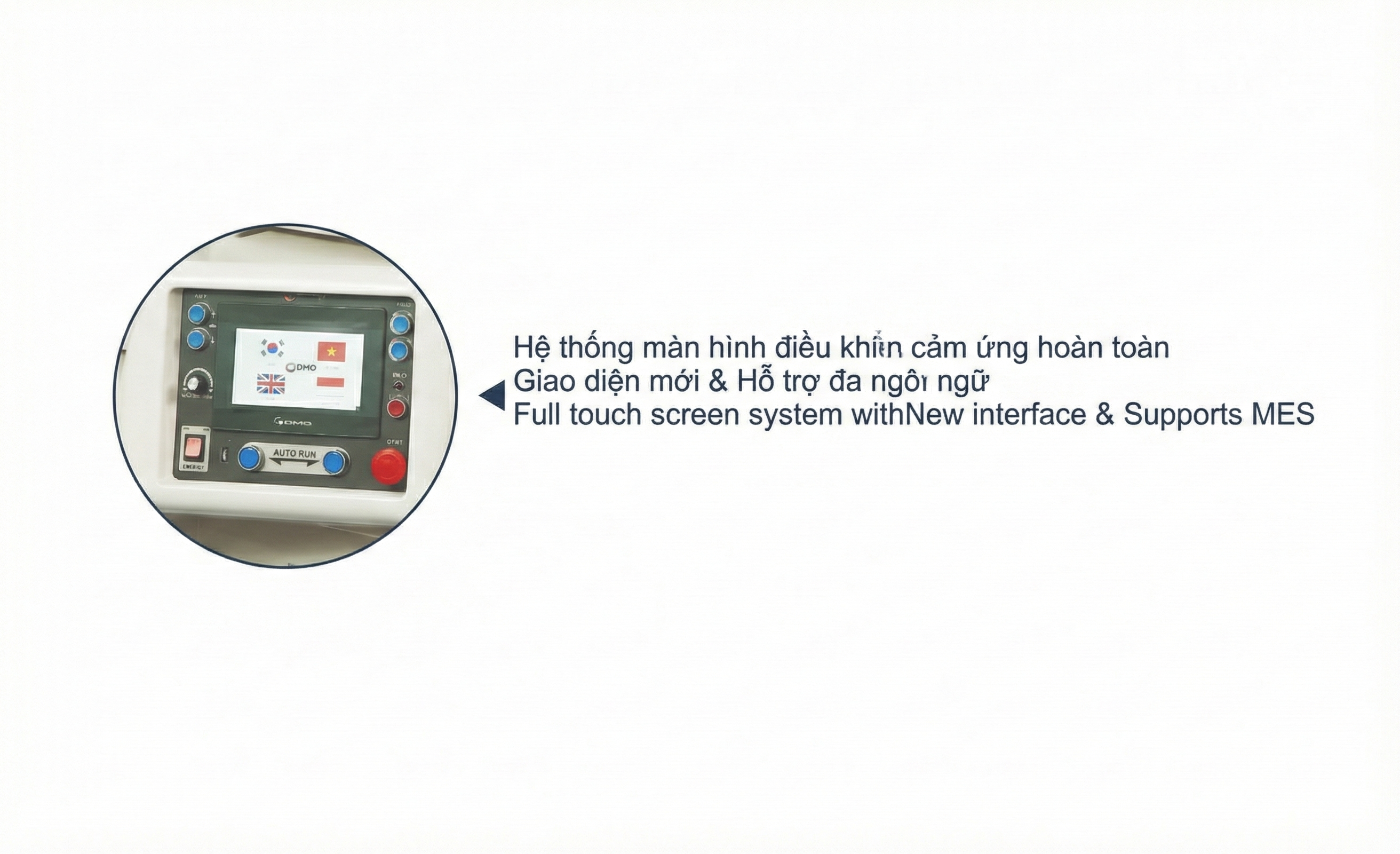

3. Automation & Absolute Precision

The MFS-ST200 eliminates time-consuming manual adjustments through advanced automation:

Automatic edge alignment: Sensors automatically detect and adjust to keep fabric edges perfectly straight.

Intelligent height control: The cutting head automatically lifts according to the actual thickness of the fabric lay.

Spreading width recognition: Automatically detects the spreading width and sets the cutter travel based on the actual fabric width.

4. Powerful & Versatile Operation

Designed for long-term industrial use, the machine offers multiple user-support features:

Speed switching: Integrated 2 speed patterns switching to suit different spreading stages.

Troubleshooting support: Manual control mode allows operators to easily rewind fabric or cut off defective sections directly on the spreading table.

Expansion option (ST200F option): For factories that also process folded fabrics, an optional auxiliary fabric support table can be added, transforming the machine into a “2-in-1” solution.

Conclusion

The BMO MFS-ST200 is a reliable "supporter" for garment factories specializing in denim, felt, and other heavy fabric products. With outstanding load capacity combined with servo-driven precision, it is the perfect solution for ensuring semi-finished fabric quality right from the very first production stage.

Looking for an optimal fabric spreading solution for your production line? Contact us today for in-depth consultation and firsthand experience of the performance of BMO fabric spreading machines.