Description

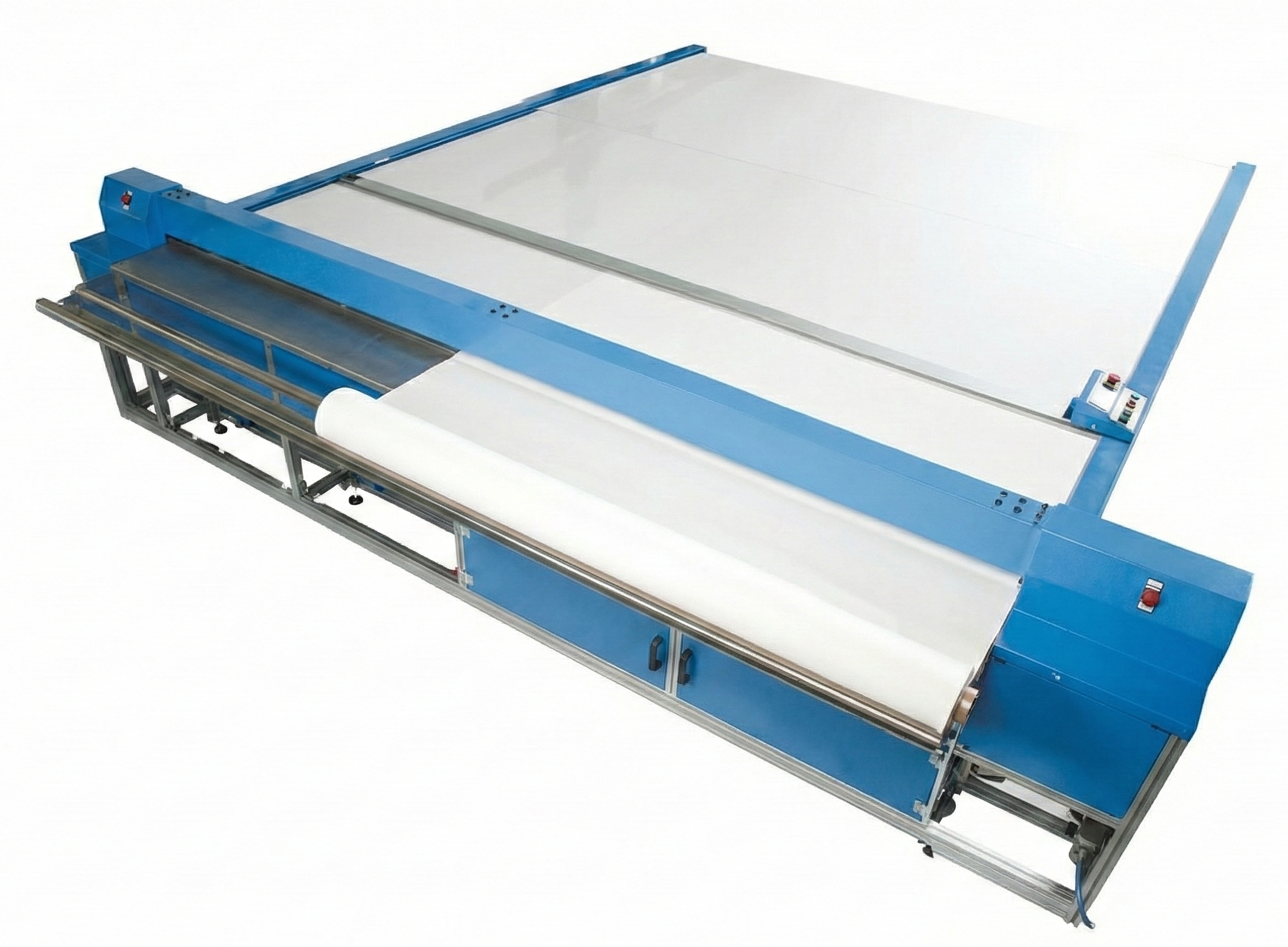

BMO SCM-130HS: A Dedicated Hot Cutting & Edge-Sealing System for Synthetic Fabrics and Vertical Blind Fabrics

For synthetic fiber materials such as polyester, nylon, as well as curtain cords, safety belts and webbing, conventional blade cutting often causes frayed edges, loose fibers, and reduced durability. The BMO SCM-130HS is a dedicated hot knife cutting solution that uses high temperature to instantly seal the cut edges, delivering clean, sharp, and long-lasting finished products.

1. Specialized Hot Knife System

The machine operates by heating the cutting blade so that it simultaneously cuts and melts the material edges. This process bonds the fibers together at the cut surface (edge sealing), completely eliminating fraying or fuzzing commonly seen in vertical blind fabrics and woven webbing.

2. Mastering Thick Materials & Heavy-Duty Webbing

The biggest challenge in hot cutting is handling very thick materials such as safety belts, backpack straps, or lifting slings.

If the blade cuts too quickly, the material will not separate; if it stays too long, it may burn or scorch.

The SCM-130HS overcomes this with its Hot Knife Applying Time Control feature:

Users can precisely set the contact and heating time of the blade on the material.

This allows the machine to cut cleanly through even extremely thick and rigid webbing that standard cutting machines cannot handle.

3. Optimized for Elastic Materials

The machine is equipped with a special operating mode designed for soft and elastic materials, including woven fabrics containing rubber fibers.

This mode controls material tension and feeding speed, ensuring that the final cut length remains accurate according to the preset value, without the common issue of materials “shrinking back” after cutting.

4. Automatic & Intelligent Operation

BMO equips the SCM-130HS with advanced management features to reduce operator workload:

30-Job Memory: Stores parameters for up to 30 frequently used orders, enabling fast job switching.

End-of-Material Sensor: Automatically stops the machine and alerts the operator when the input roll runs out.

Manual Control Mode: Makes threading, alignment, and pre-operation setup easier and more precise.

Conclusion

If your business specializes in products made from synthetic fibers such as curtain cords, webbing, elastic bands, or nylon ropes, the BMO SCM-130HS is the most accurate investment choice. Rather than combining multiple functions, it focuses on doing one thing exceptionally well: perfect hot cutting and edge sealing, even for the thickest and most demanding materials.

Contact us today to receive a detailed quotation for BMO specialized blind cutting machines.