Description

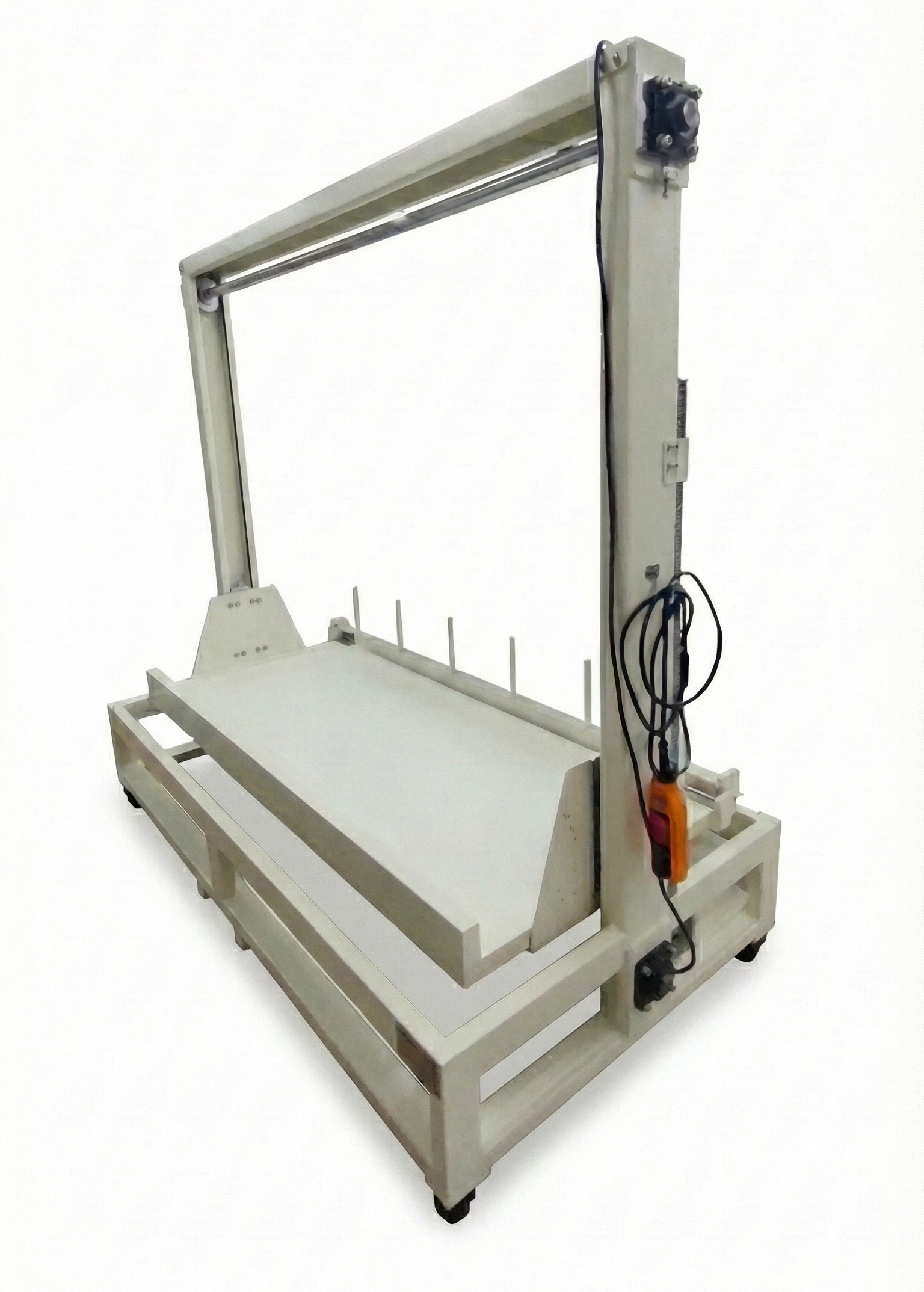

BMO LFA-250: Automatic Fabric Roll Lifter – A Reliable “Assistant” for Feeding Heavy Fabric Rolls

In industrial fabric spreading operations, manually lifting and loading heavy fabric rolls onto the spreading table is difficult and potentially hazardous for workers. The BMO LFA-250 is specifically designed to automate this process, allowing heavy fabric rolls to be fed into the BMO fabric spreading machine smoothly and with absolute safety.

1. Powerful 250 kg Lifting Capacity

As its name suggests, the LFA-250 offers impressive load-bearing capability. The unit can lift fabric rolls weighing up to 250 kg.

This makes it an indispensable solution for factories working with denim, thick fleece, or large-width fabric rolls.

2. Simple & Safe Operation

BMO places maximum emphasis on safety and convenience:

Hand controller: All lifting and lowering operations are performed via a handheld controller. Operators can stand in the best viewing position to control the process, ensuring the fabric roll is accurately positioned onto the support shaft without physical strain.

Optimized lifting speed: It takes only about 18 seconds to raise a heavy fabric roll from the floor to the ready-to-spread position, significantly reducing downtime during material feeding.

3. Purpose-Built for BMO Spreading Machines

The LFA-250 is designed to work in perfect synchronization with BMO fabric spreading machines. Its lifting mechanism matches the height and loading position of the spreader, forming a closed, professional, and efficient feeding system.

4. Flexible Customization Options

In addition to the standard configuration, the machine can be customized to suit the specific needs of each factory:

Roll diameter: Standard handling for fabric rolls up to 1,000 mm in diameter (customizable upon customer's request).

Power supply: Uses common single-phase 220–230V power, making installation easy.

Conclusion

The BMO LFA-250 is more than just a lifting equipment, it is a solution that protects worker health while maintaining continuous production flow. If your operation involves heavy fabric rolls, this is an essential addition to optimize the performance of your BMO fabric spreading machine.