Description

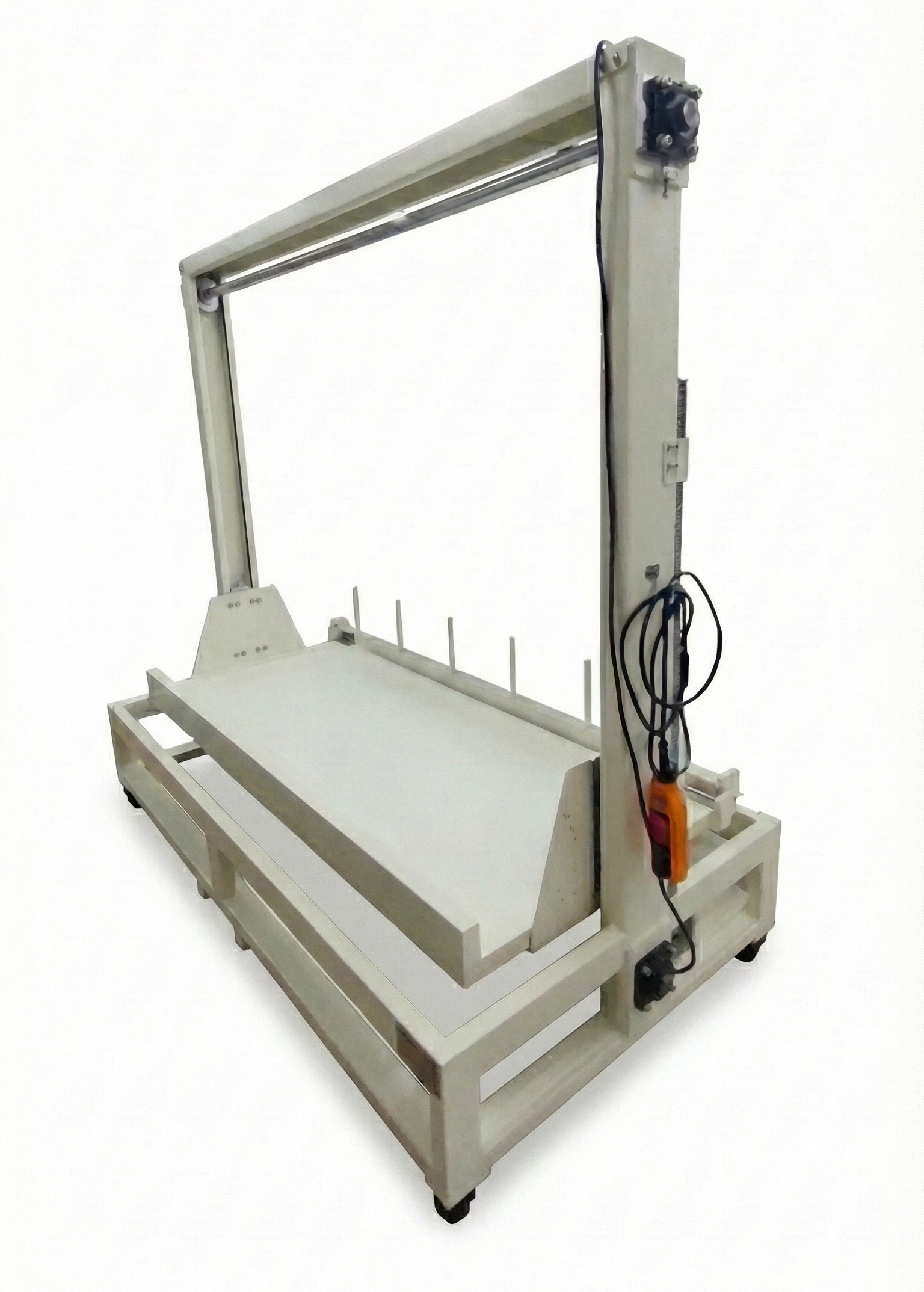

Fabric Flotation Table: High-Speed Air Cushion Fabric Transport System

In industrial garment production lines, transferring fabric stacks from the spreading area to the cutting area requires precision and significant physical effort. The Fabric Flotation Table is an advanced internal transport solution that utilizes aerodynamic principles to minimize friction. This allows for the flexible and effortless movement of heavy fabric stacks while preserving the structural integrity of the bottom fabric layer.

1. Air Cushion Technology for Friction Reduction

The table surface is machined to a thickness of 30mm and features a strategically arranged system of technical air holes. During operation, high-pressure air is forced upward from below, creating a thin air cushion that separates the table surface from the fabric stack.

This mechanism almost completely eliminates static friction. Consequently, operators can easily push and maneuver heavy fabric stacks across the table with minimal effort, ensuring that the fabric layers remain aligned and undistorted.

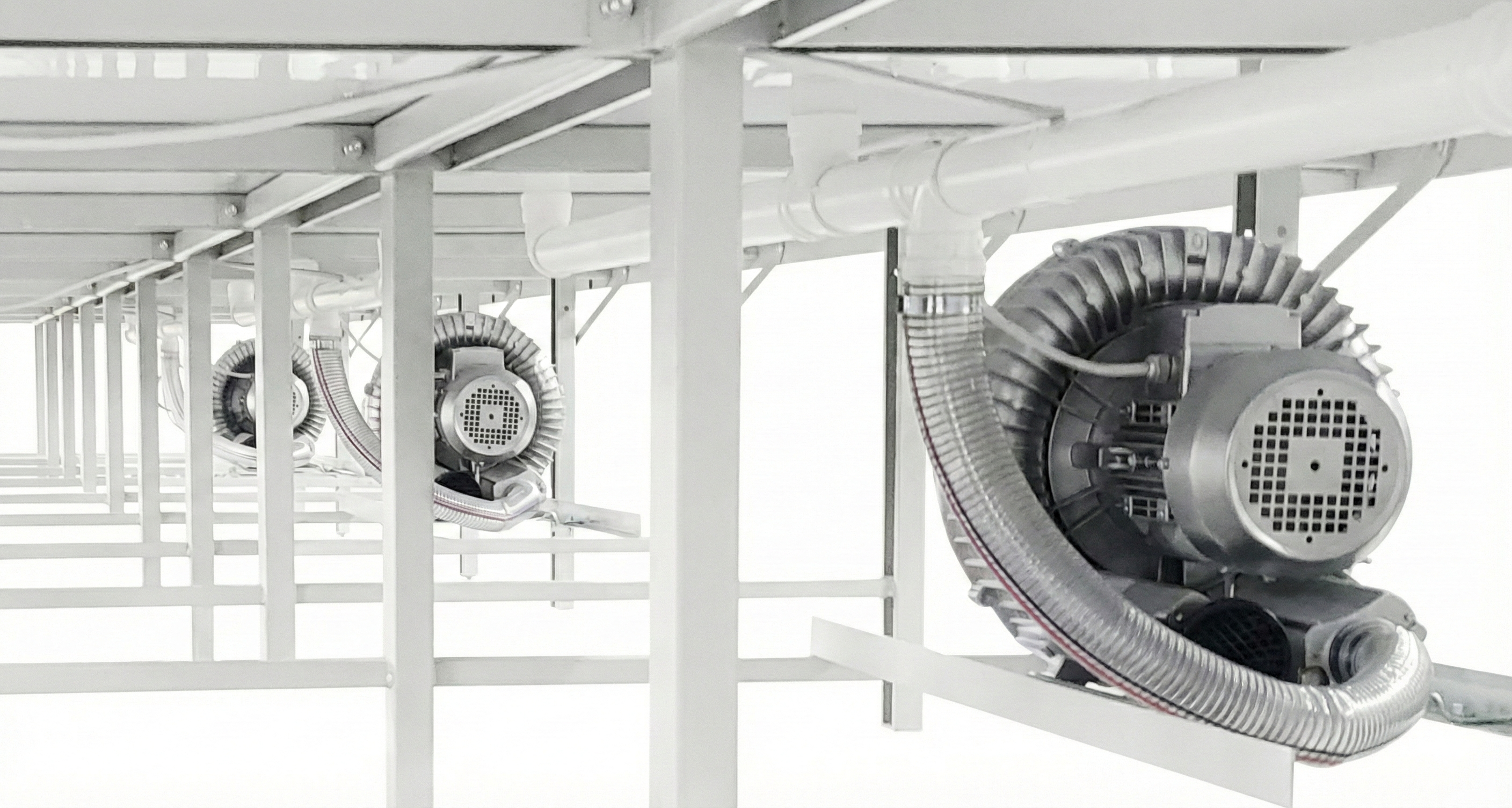

2. Powerful Air Blower Motor Performance

The system is driven by a specialized Model XWB-3 air blower motor, ensuring a stable and continuous airflow across the entire table surface:

Operating Power: A powerful 2.2 kW motor operating at a speed of 2820 rpm.

High Airflow Volume: Delivers an airflow of $260 m^3/h$ with a maximum pressure of 33 kPa. These specifications ensure effective lifting capabilities even for thick materials like Denim, Felt, or high-density fabric stacks.

3. Flexible Modular Design & Optimized Operation

The Fabric Flotation Table is designed according to ergonomic standards with high customizability to fit various factory layouts:

Modular Structure: The table is assembled from standard sections with a length of 1200mm. This design allows factories to easily expand or shorten the conveyor length based on actual production needs.

Diverse Dimensions: Offers 3 table width options (1830mm, 2130mm, 2330mm), compatible with common spreading and cutting machine sizes.

Height Adjustment: The table legs allow for height fine-tuning from 830mm to 870mm, facilitating height synchronization with other equipment and creating the most comfortable working posture for operators.

Conclusion

The Fabric Flotation Table is an essential auxiliary device that optimizes the workflow between the spreading and cutting stages. With its high-power motor and smart air cushion design, the product helps businesses improve labor productivity, reduce physical workload, and ensure the integrity of semi-finished products.